Richard Kablitz was born in Riga on 20th May 1868. He studied at the Technische Hochschule (technical university) in Riga and worked as an assistant professor for mechanical engineering after four years.

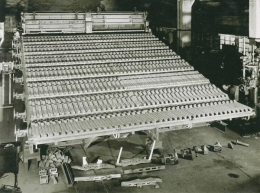

He invented and developed gilled cast iron tubes. The Kablitz ribbed type tube economiser suddenly conquered the Russian market. Consequently, all plants belonging to the Russian government in the border provinces were relocated to the interiors during the First World War.

He invented and developed gilled cast iron tubes. The Kablitz ribbed type tube economiser suddenly conquered the Russian market. Consequently, all plants belonging to the Russian government in the border provinces were relocated to the interiors during the First World War.

With some personalities from the Baltic industry, Richard Kablitz founded the “Rigaer Gesellschaft für Oekonomie der Dampferzeugungskosten und Feuerungskontrolle” (Rigaer Society for Economy of Steam Generation Costs and Heating Control), a company that aimed at constant improvement in the efficiency of steam generation plants.

After the formation of the Latvian government and the Soviet Republic, the Kablitz family moved back to Riga. An engineer’s office, which got a manufacturing and marketing approval for the new employees, was left behind in Moscow.

In the meantime, not only the economiser, but also the Kablitz universal high-power overthrust heating system was developed. From 1928-1930, Kablitz invented and developed cast iron ribbed plate heat exchangers.

Then came the breakdown, followed by another flee to the West wherein all tangible and intangible assets were left behind.

The Americans brought the inventor Richard Kablitz and his family to Marbach near Lauda in the summer of 1945. With great difficulties, the new plant was set up in Lauda, wherein particularly the employees that were already a part of the workforce before, had to be brought to Lauda.

The technical edge, the new markets and the orders from Onassis for 24 large tankers, which were equipped with Kablitz-products, helped the company grow fast.

Kablitz gave away construction licenses to big foreign companies because of which the products of the German Richard-Kablitz-Gesellschaft (company) were used worldwide. They were mainly used in heat recovery in steam boilers, refineries and chemical and environment protection plants.

With its experience, the company earned name for itself as a competent partner in biomass power station and plant construction, and extended its scope of delivery and services to complete biomass thermal power stations including fuel supply and conveying technology, heating systems, steam boilers and flue gas cleaning.

With the development of complete heating and boiler systems, the angular secondary burning chamber that ensures the best burn-out results with wet fuels was patented by Kablitz in 1993.

Due to the eco-political development in the 21st century, the company’s markets for wooden composite and sawmill industry have also expanded to power suppliers and communes.

Even in future, the company will continue to develop its business nationally as well as internationally because although the company is located in Lauda, the field of action is the whole world.