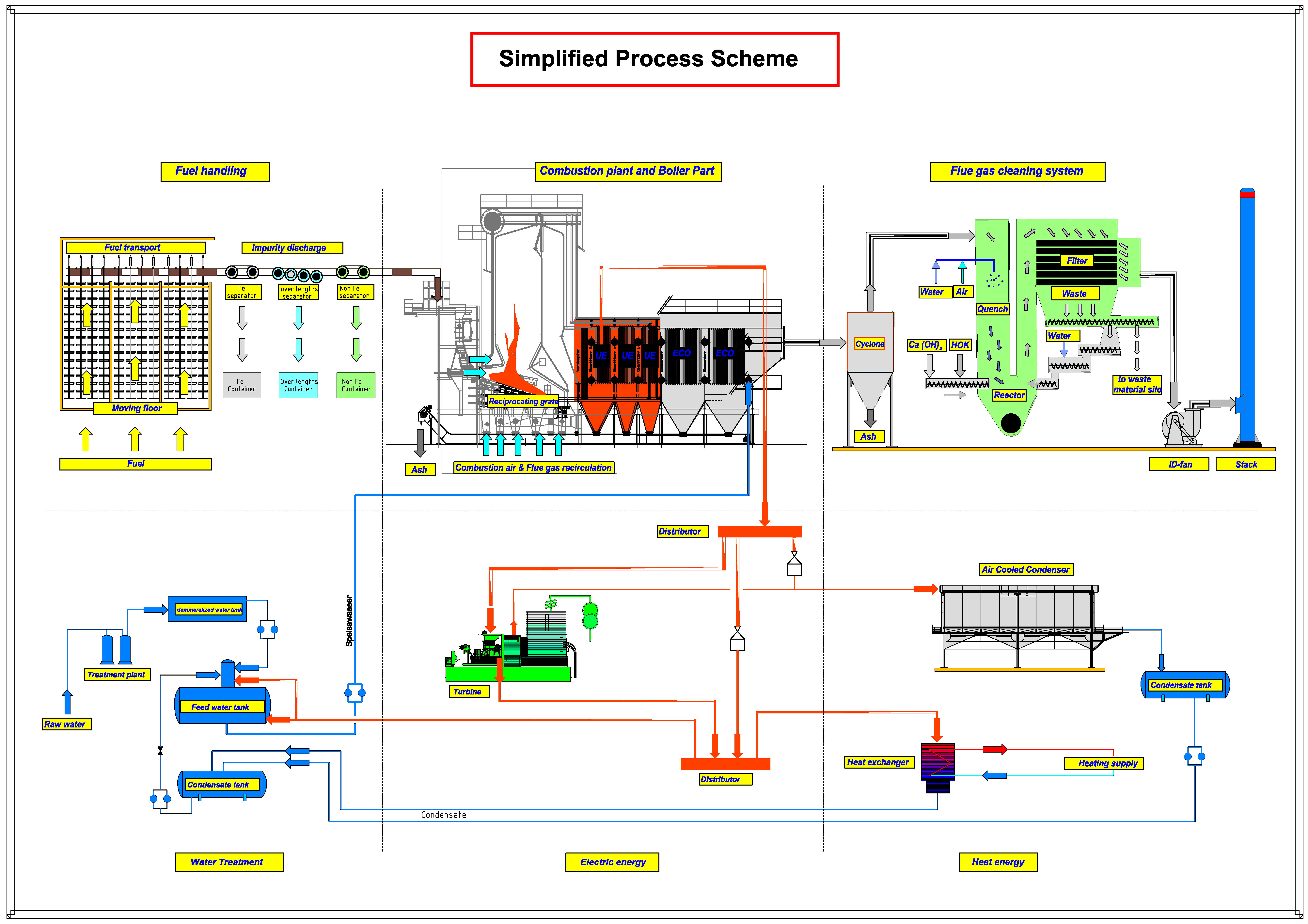

Las calderas de vapor son muy versátiles. El vapor permite calefaccionar procesos y áreas así como generar energía mediante turbinas, con lo cual es posible implementar casi cualquier configuración imaginable.

Combinamos calderas con nuestros versátiles sistemas de combustión Kablitz, ofreciendo así a nuestros clientes conjuntos completos óptimos, de una sola mano.

Nuestra especialidad es suministrar toda la tecnología para una planta de generación, desde el almacenamiento de combustible hasta la chimenea, pasando por la generación de energía y el suministro de calor, todo a la medida exacta de sus necesidades.

Suministramos diferentes diseños de calderas para cada aplicación:

- Tradicionales calderas hidrotubulares para biomasa, de hasta aprox. 120 MW, con presiones de hasta aprox. 100 bar y 520°C

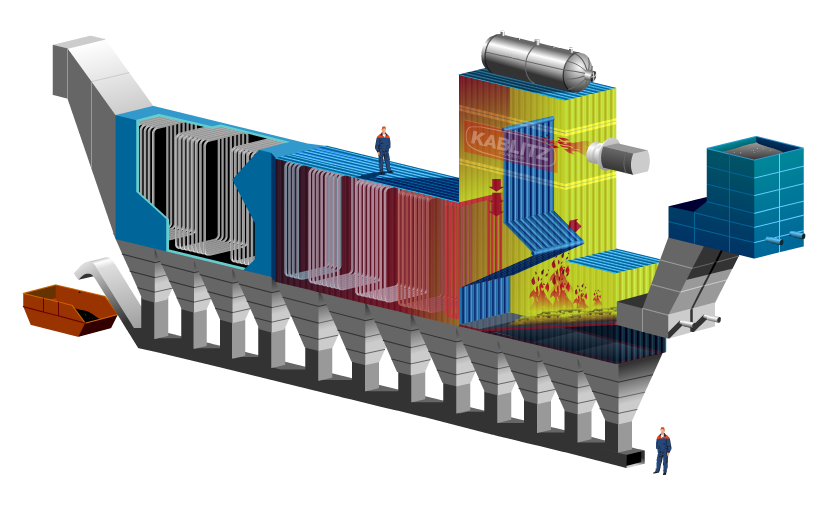

- Calderas hidrotubulares horizontales, también llamadas calderas de cola, para la combustión de desechos de madera y RDF/SRF

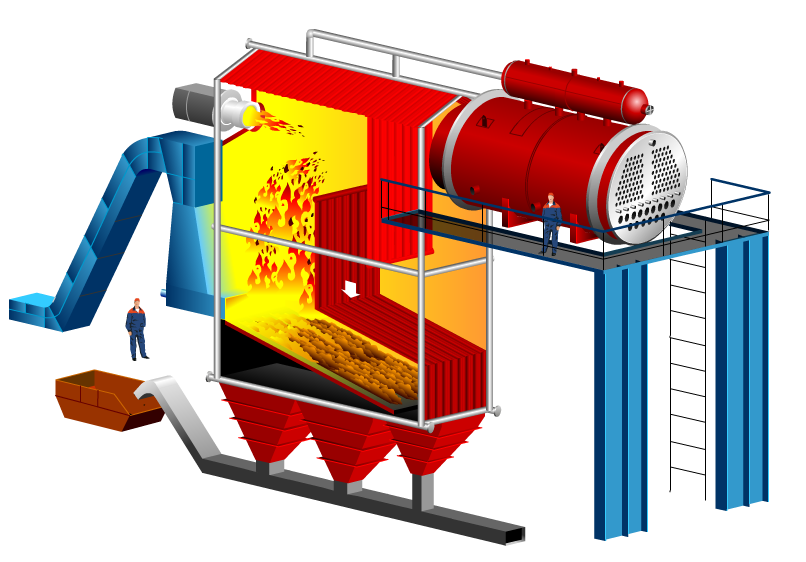

- Calderas pirotubulares con etapa de enfriamiento hidrotubular (caldera combinada) para presiones de hasta aprox. 40 bar y 40 t/h de vapor

Referencias

| Technical Data Goch | Heißgaserzeuger mit Restholzfeuerung | ||

| Fuel: | Wood residues, landscape maintenance material | Process steam offtake: | max. 27,0 t/h |

| Calorific value range: | 1,5 - 3,2 kWh/kg | Steam output: | 30,0 t/h |

| Annual fuel throughput: | approx. 100,000 t | Steam temperature: | 480 °C |

| Firing capacity: | Reciprocating grate: 28.0 MW | Steam pressure: | 65 bar (a) |

| Electrical power: | 5,0 - 7,2 MW | Feed water temperature: | 107 °C |

| Commissioning: | 2012 |

In terms of flexibility, it was also of great importance to achieve a high fuel flexibility in order to be prepared for any eventuality. For this reason, a steam-air preheater was installed which enables fast and precise temperature control and, together with the economiser, also ensures a good plant efficiency. Due to the flexibility of the furnace and the turbine as well as the design measures to reduce the corrosion risk, the plant works economically and reliably in all operating con- ditions.

The optimal concept of combined heat and power generation has proven itself in practice: During the week, the power plant supplies the adjacent potato refining plant with inexpensive process steam, so that approx. 5.0 MW of electrical energy can be generated, whereas at the week- ends an increased electrical output of approx. 7.2 MW can be produced without any heat dissipation.

| Technical Data Wiesbaden | Heißgaserzeuger mit Restholzfeuerung | ||

| Fuel: | A I - A IV wood waste | Steam output: | 49,0 t/h |

| Calorific value range: | 2,7 - 3,8 kWh/kg | Steam temperature: | 425 °C |

| Annual fuel throughput: | approx. 100,000 t | Steam pressure: | 42 bar (a) |

| Firing capacity: | Reciprocating grate: 38.4 MW | Feed water temperature: | 120 °C |

| Electrical power: | 10,0 MW | Commissioning: | 2013 |

| Process steam offtake: | 24,0 MW |

It was important for the customer to generate electricity and heat with optimum efficiencies and not only to comply with the required emission values, but even to significantly undercut them. In order to meet these emission requirements, a multi- stage selective non-catalytic reduction plant (SNCR) with acoustic temperature measurement, a sophisticated flue gas cleaning system with evaporative cooler and a dry sorption with additive addition of lime hydrate and activa- ted lignite HOK are used.

Due to the difficult and polluted fuel, the horizontal steam boiler was designed in such a way that corrosion and erosion risks are minimal by also enabling an easy and fast replacement of the heating surfaces if necessary.

| Technical Data Czarna Woda | Heißgaserzeuger mit Restholzfeuerung | ||

| Fuel: | Wood chips, wood veneer, bark | Steam output: | 30,0 t/h |

| Calorific value range: | 1,9 - 3,9 kWh/kg | Steam temperature: | 260 °C |

| Annual fuel throughput: | approx. 75,000 t | Steam pressure: | 27 bar (a) |

| Firing capacity: | Reciprocating grate: 22.9 MW | Feed water temperature: | 105 °C |

| Dust/granulate nozzles: | 7,2 MW | Commissioning: | 2017 |

steam generator

The natural circulation steam generator implemented by Kablitz was designed as a combination of water tube and smoke tube evaporator. In this case, a second drum was added to the smoke tube. This upper drum is required due to the steam pressure and the high boiler output (for smoke tube boilers) in order to ensure a sufficiently large volume. In addition, an economiser was installed downstream to increase the efficiency. In addition, the plant has a fly ash recirculation system to improve burnout and make optimum use of the fuel.

In order to ensure the longest possible availability, special sootblower systems were used to clean the superheater, flue tube and economiser heating surfaces, enabling the boiler plant to be cleaned fully automatically during operation. By switching to renewable energy sources and using pro- duction waste, the company not only saves money in the long term, but also contributes to a clean environment.

| Technical Data Permuco | Heißgaserzeuger mit Restholzfeuerung | ||

| Location: | Chile, Region BioBio | Firing capacity: | 62,0 MW |

| Fuel: | Wood chipping from pine, poplar, eucalyptus up to 20 % stone coal, 4.5 MW heat output with biogas | Steam output: | 66,0 t/h |

| Calorific value range: | 1,6 - 3,1 kWh/kg | Steam temperature: | 485 °C |

| Annual fuel throughput: | 306.600 t | Steam pressure: | 76 bar |

| Feed water temperature: | 120 °C - 130 °C | ||

| Commissioning: | 2015 |

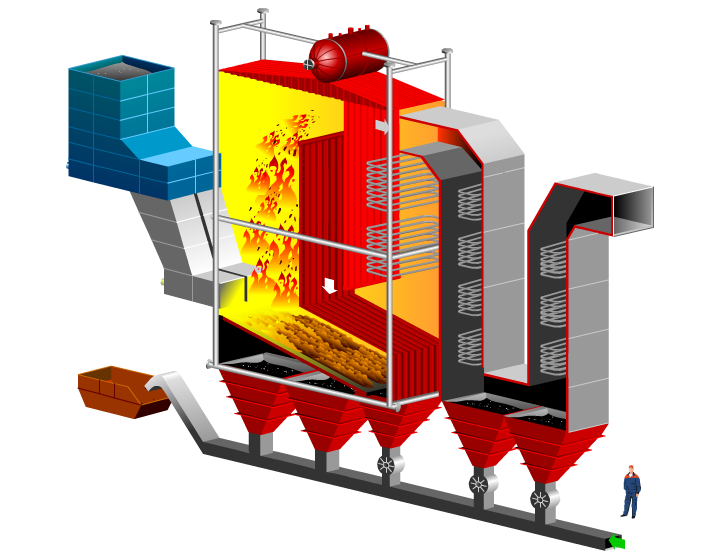

vertical boiler

In addition, the task was to co-fire up to 20 % hard coal with the wood shredder material and to generate a ther- mal output of 4.5 MW with biogas.

The biomass fuel is transported to the furnace by a con- veyor. In addition to the biomass fuel store, there is also a coal bunker from which the hard coal is additionally dosed onto the conveyor via screws. The biogas is thermally utilised in the first boiler pass with a specially designed burner.

A further highlight in addition to the multi-fuel technology is the boiler design. Due to the high seismic activity in this region, the boiler was designed as a suspended boiler in order to withstand even the strongest vibrations caused by earthquakes.

| Technical Data Incheon | Heißgaserzeuger mit Restholzfeuerung | ||

| Fuel: | A I - A IV wood waste | Steam output: | 64,0 t/h |

| Calorific value range: | 2,9 - 5,2 kWh/kg | Steam temperature: | 425 °C |

| Annual fuel throughput: | ca. 140.000 t | Steam pressure: | 64 bar (a) |

| Firing capacity: | 38.4 MW Water-cooled reciprocating grate 715 | Feed water temperature: | 143 °C |

| Dust/granulate nozzles: | 16,0 MW | Thermal oil capacity: | 7,2 MW |

| Electrical power: | 9,9 MW | Thermal oil supply: | 290°C |

| Process steam offtake: | 24,0 MW | Thermal oil return: | 245°C |

| Commissioning: | 2019 |

Another special feature of this plant is the water-cooled feed grate type 715, which is used due to the very high calorific value of the waste wood.

Kablitz supplied an extremely flexible system. The custo- mer can burn his various production wastes either via the water-cooled grate or the dust/granulate nozzles. The steam boiler supplies live steam for a turbine for ener- gy generation and process heat and the thermal oil boiler supplies thermal energy to two MDF presses via a 300 m long ring line. The customer generates environmentally friendly energy through the energetic utilisation of the residual materials from production. He can produce steam for his power generation as well as hot thermal oil with only one plant, thereby reducing his dependence on oil.

The combination of grate firing and dust/granulate nozzles allows a quick adjustment of the output to fluctuations of the heat consumers.