Glass tube heat exchanger

The residual heat in the flue gas must be utilised completely in order to reach a high efficiency. Since the acid dew point can be undershot on this occasion, the Kablitz glass tube heat exchanger is connected downstream.

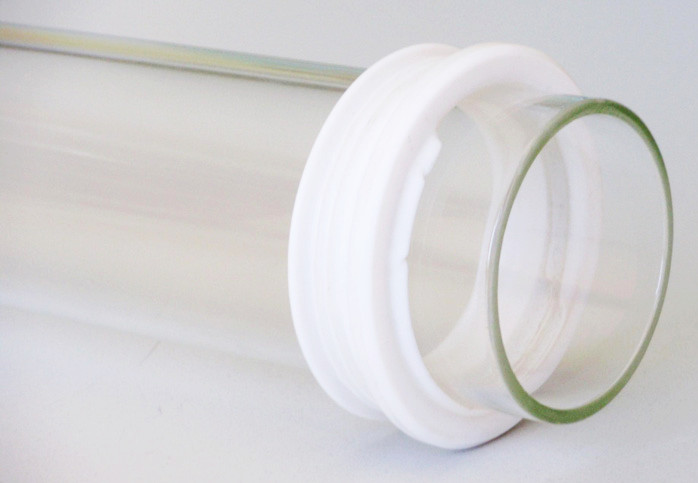

It is corrosion-resistant owing to its heating surfaces made of borosilicate glass which is resistant to acids. Steel parts exposed to flue gas are protected from corrosion due to a PTFE coating and the sealing of the individual glass tubes is also achieved through PTFE gaskets.

The PTFE coating of the steel parts exposed to flue gas and the gaskets are successfully being used since decades.

Due to the special materials used, the temperature of the heating medium is limited to 260 °C.